What is Hydrographics?

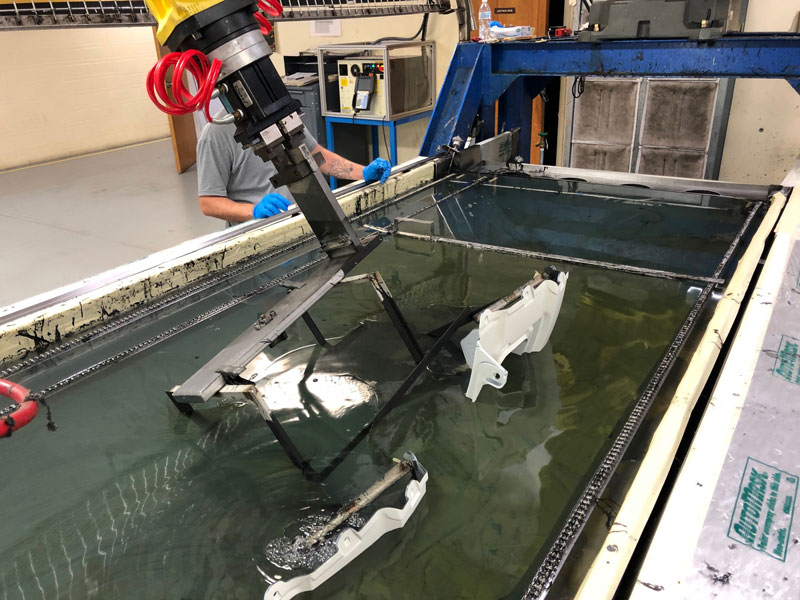

Hydrographics is when a dissolvable-printed film floats on a tank filled with water. Placing objects into this tank is also referred to as Immersion Printing, Water Transfer Printing, and Hydro Dipping. The imagery below is footage of what the hydrographics process looks like as OEM parts are dipped into the tank.

Hydrographic finishing provides complete 360° coverage over corners and in the crevasses of the most difficult three-dimensional parts.

Hydrographics provides a very durable finish. A company proficient in hydrographic technology tests for the following demanding standards: hardness, UV resistance, chemical resistance, and adhesion to the substrate.

Larger, industrial companies integrate automation to provide consistent and repeatable finishes.

What types of parts can Hydrographics be used on?

Type:

Hydrographics can be used on 2D and 3D plastic or metal parts. The types of parts can vary, used in multiple industries – heavy-duty truck, off-road vehicles, military, office equipment, household appliances, personal care products, plus many more. We can also discuss the opportunity to customize. See our gallery for ideas!

Size:

Size limitations are restricted by the size of the dip tank, however there are many tank options to accommodate many different size parts, as small as a personal care product and as large as a hood of an off-road vehicle. Credible industrial hydrographics companies typically have large tanks utilizing robotics to process the parts.

Process

Hydrographics vs. Paint

Hydrographics is a premium finish compared to paint that gives your product differentiation from the competitors. With paint, you are limited to various colors. With hydrographics, your product can be transformed into a simulated wooden part, carbon fiber, brushed metal, or a camouflage part. The design opportunities are unlimited, and your existing parts can be decorated without modifications to the actual part.

Durability:

The polyurethane clear coat gives the hydrographic decoration properties similar to an automotive paint system. The process meets or exceeds most OEM specifications for quality.

Most large companies can perform durability and other testing in-house.

Types of Finishes

Hydrographics allows customers to customize their products to stand out against their competition. A wide variety of films are offered – wood grains, marbles, camouflage, brushed metals, and an opportunity to customize.

Testing:

State-of-the-art testing equipment can be used to ensure that processes are in control and meeting customer requirements. Some typical in-house testing equipment is listed below:

- X-Rite Spectrophotometer – measures relative color values

- Fisher Dualscope – measures coating thickness

- Gardco Gloss Meter – measures relative gloss values

- Microview Microscope – analysis if film builds and defects