FinishTEK has been providing custom hydrographics for low and high-volume parts for over 25 years in the power sports, automotive, appliance, agriculture, and other industries. Hydro dipping, also known as Immersion Printing, is a process of transferring colors and patterns onto various materials. The resulting look is 360-degrees of awesome. But does hydro dipping wear off?

Understanding hydro dipping is important for understanding its longevity. Any part or material we receive for hydro dipping is tested for paint adhesion. If there is no paint adhesion during testing, the product will not be dipped. However, this is very unusual because FinishTEK uses the most advanced chemistry and techniques available to ensure a quality finish on any product or part.

Hydrographics are preserved by a series of paint and clear coat layers. First, all materials are base painted. We offer several different options for these adhesion promoters to best match your needs. After the base coat, the product is dipped and covered by the hydrographic which bonds to the base paint. As long as the base paint remains stable, the hydrographics will remain intact.

Because all hydrographic film is printed with the same inks, there is no quality lost due to the particular color or pattern you choose. As a final step, we apply an automotive-grade clear coat to the finished product. This clear coat protectant has U.V. inhibitors that protect the finish from fading.

Hydrographic finishes are very robust and will last for many years under normal use. However, similar to your car finish, the paint can scratch if the product is abused. Scratching the protective clear coat can cause failure to the hydrographic finish.

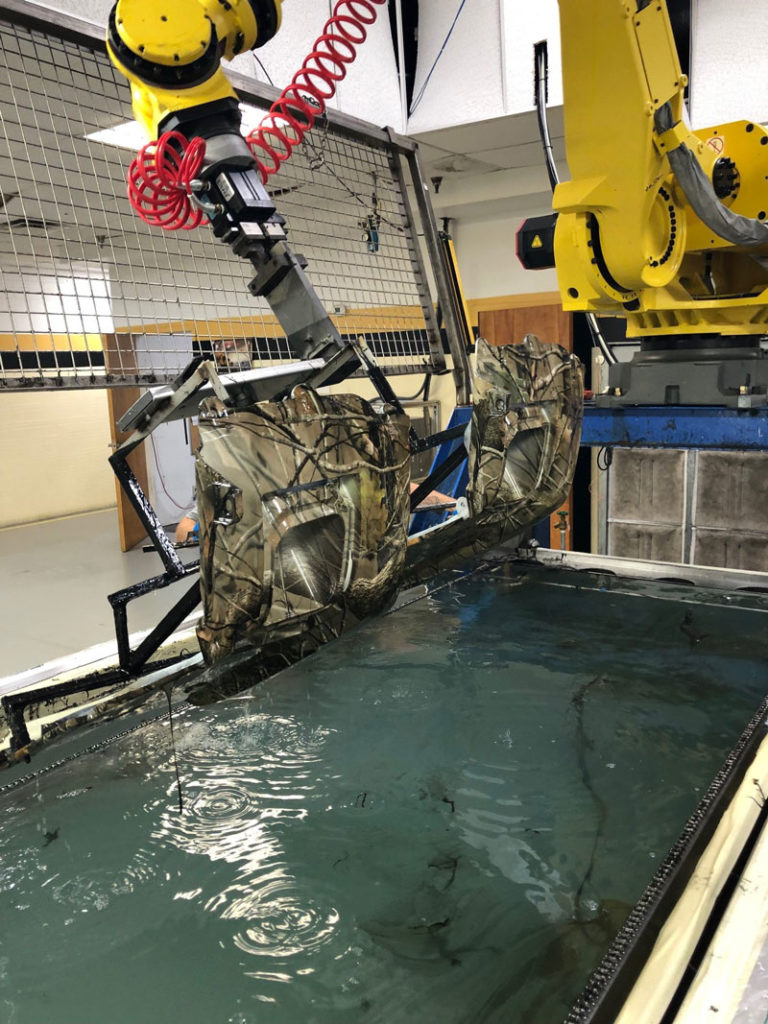

If you’re looking for options to add graphic prints or colors to your products or parts, look no further than hydro dipping from FinishTEK. We have decorated everything from ATV’s, auto parts, and appliances to bike helmets and floor tiles. We utilize two robotic dipping lines as well as a manual dip tank for sampling and smaller production runs. Call FinishTEK today to get started on your hydro dipping project.